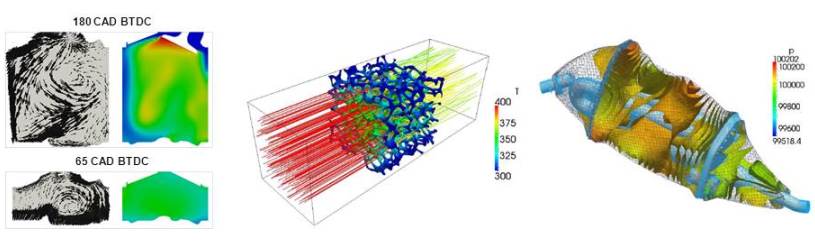

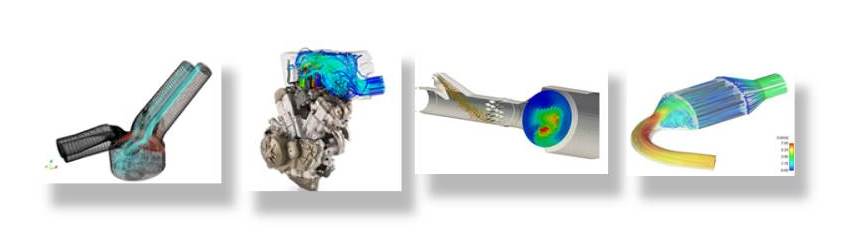

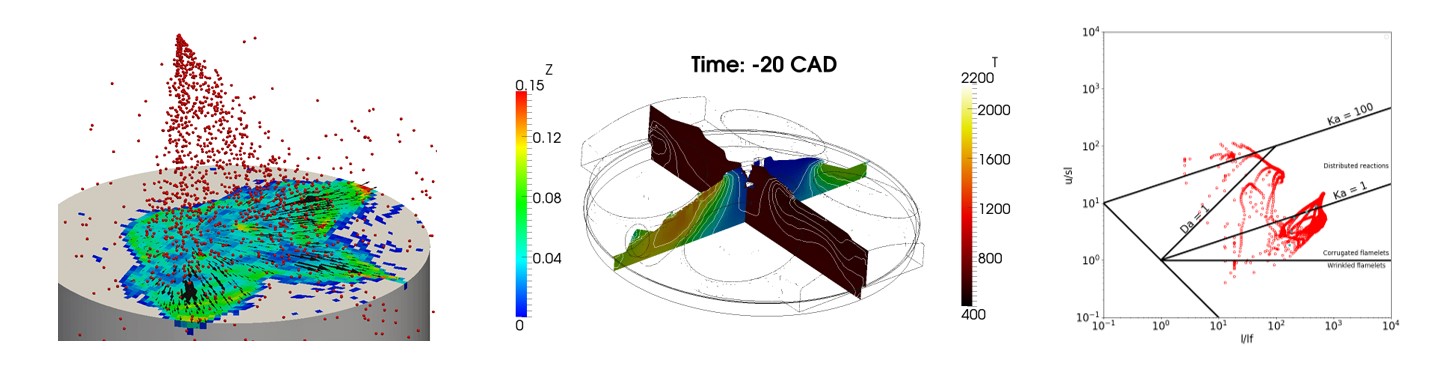

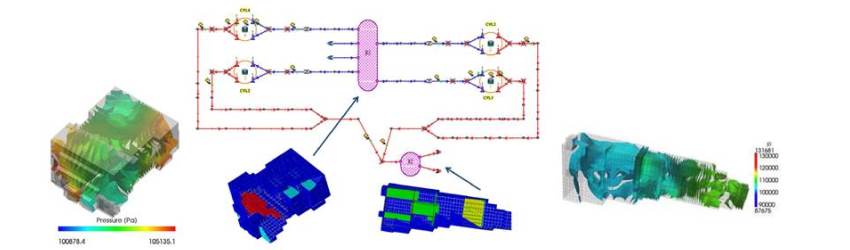

Moving mesh algorithms for complex geometries

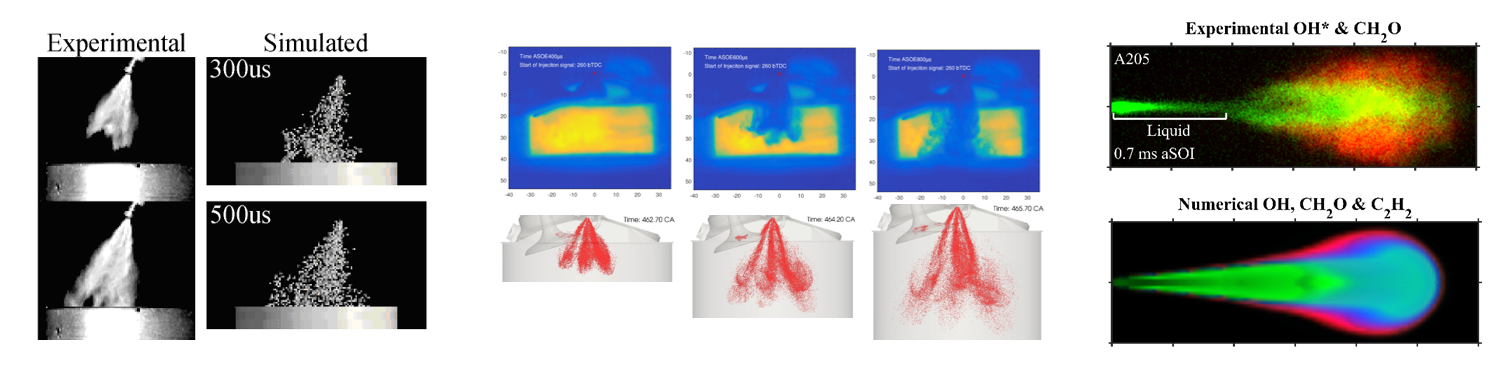

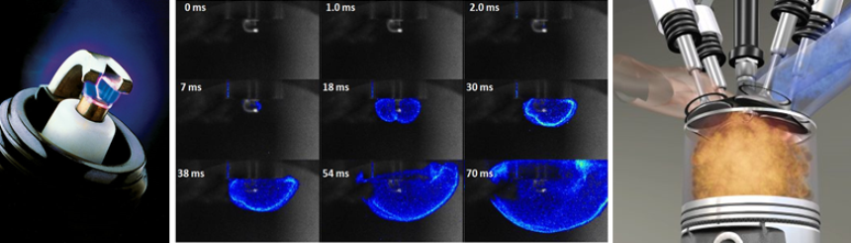

Multi-dimensional simulations of internal combustion engines involve non-stationary turbulent flows and require advanced physical and numerical models to handle multiple interacting

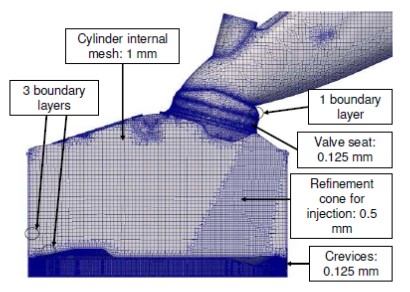

thermo-fluid processes in moving meshes. Unstructured, polyhedral grids discretize the engine geometry to easily account for the presence of complex features like piston bowls, cylinder head

and valves. Grid motion is  performed by two different methods referred as the immersed boundary and the body fitted approaches. The last one is widely used for its reliability since the mesh is consistent with the boundary

domain to be simulated. However, it is necessary to move the grid points to accommodate the boundary motion and this requires flexibility with respect to the mesh structure and the moving

boundaries.

performed by two different methods referred as the immersed boundary and the body fitted approaches. The last one is widely used for its reliability since the mesh is consistent with the boundary

domain to be simulated. However, it is necessary to move the grid points to accommodate the boundary motion and this requires flexibility with respect to the mesh structure and the moving

boundaries.

The research group works on this topic in collaboration with Prof. Hrvoje Jasak and Dr. Zjeliko Tukovic (FSB, University of Zagreb), Prof. Gianmarco Bianchi and Dr. Federico Brusiani (DIEM, University of Bologna).

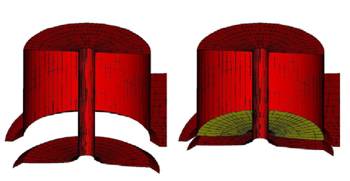

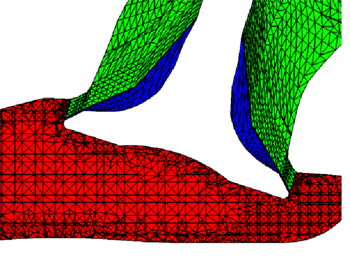

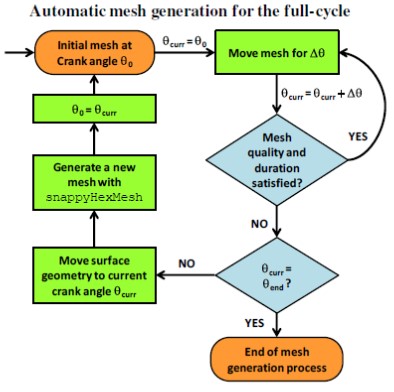

The proposed approach to handle mesh motion for IC engine geometries employs a multiple number of meshes, so that each mesh is valid for a certain crank angle interval, in which the grid points

are moved and the grid topology is eventually changed. The duration of this interval depends on how the quality and the size of the provided grid change during the motion. Eventually, if topology

modifiers are extensively used and the geometry to be simulated is rather simple, the whole simulation may be performed with only one mesh. An automatic mesh motion technique was developed

to accommodate the motion of internal grid points according to the prescribed boundary motion. The point displacements are calculated by solving a motion equation with the prescribed boundary

motion as boundary condition. Polyhedral meshes are supported and a vertex-based solution method is used to avoid the need for interpolation. To avoid degenerated cells, the motion equation is

discretized on a Finite-Element decomposition of the polyhedral mesh. Each cell is consistently decomposed on-the-fly into tetrahedra by dividing its faces into triangles and introducing a point in

the cell centroid. The Laplace equation is chosen to govern the mesh motion, and it is solved for the point velocity field which is then used to modify the point positions. To further control the mesh

quality it is possible to specify a priori the motion of the grid points before solving the Laplace equations in regions where the boundary deformation is very high or the flow is extremely grid

dependent.

The proposed approach to handle mesh motion for IC engine geometries employs a multiple number of meshes, so that each mesh is valid for a certain crank angle interval, in which the grid points

are moved and the grid topology is eventually changed. The duration of this interval depends on how the quality and the size of the provided grid change during the motion. Eventually, if topology

modifiers are extensively used and the geometry to be simulated is rather simple, the whole simulation may be performed with only one mesh. An automatic mesh motion technique was developed

to accommodate the motion of internal grid points according to the prescribed boundary motion. The point displacements are calculated by solving a motion equation with the prescribed boundary

motion as boundary condition. Polyhedral meshes are supported and a vertex-based solution method is used to avoid the need for interpolation. To avoid degenerated cells, the motion equation is

discretized on a Finite-Element decomposition of the polyhedral mesh. Each cell is consistently decomposed on-the-fly into tetrahedra by dividing its faces into triangles and introducing a point in

the cell centroid. The Laplace equation is chosen to govern the mesh motion, and it is solved for the point velocity field which is then used to modify the point positions. To further control the mesh

quality it is possible to specify a priori the motion of the grid points before solving the Laplace equations in regions where the boundary deformation is very high or the flow is extremely grid

dependent.

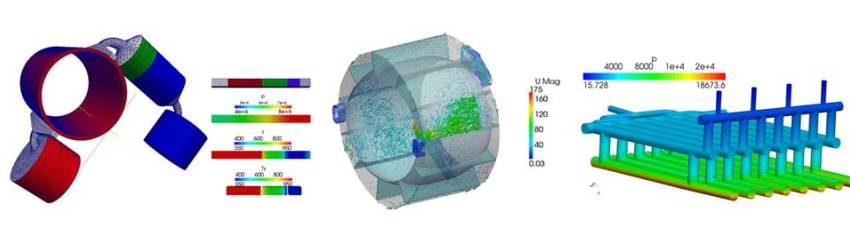

The possibility to change the grid topology is also included, to reduce the number of meshes required. Specific algorithms were implemented to handle:

- dynamic mesh layering: to keep an optimum mesh size close to the moving boundary such as piston and valves

- sliding mesh interfaces: to change dynamically the connectivity between different moving mesh regions (scavenging in a two stroke engines)

- attach-detach boundary: to deal with the valve closure event by converting a set of internal faces into two different separated regions.

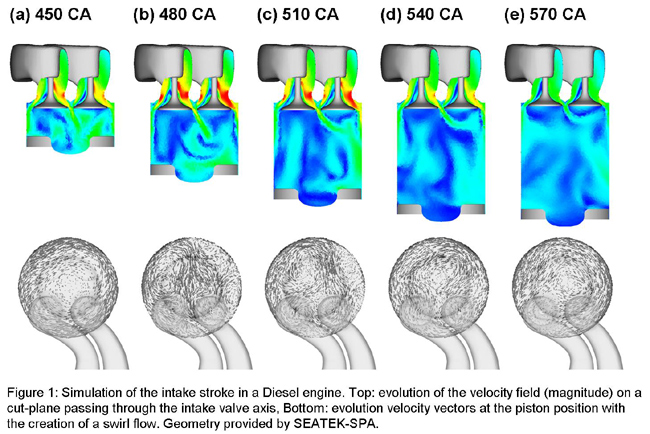

The following movies illustrate the application of the developed moving mesh strategies to the simulation of different internal combustion engine geometry:

» Valve motion with mesh deformation

» Valve motion with dynamic mesh layering and sliding mesh interfaces

» Mesh motion in a GDI Engine (geometry provided by IFP, Institute Francais du Petrol)

» Scavenging simulation in a two-stroke engine for motorcycle applications

» Simulation of the intake stroke in a GDI engine

» Simulation of the compression and the combustion phases in a Diesel Engine

Publications:

1 - Lucchini T., D'Errico G., Jasak H., Tukovic Z., Automatic Mesh Motion with Topological Changes for Internal Combustion Engine Simulations, SAE Technical

Paper 2007-01-0170, 2007.

2 - Lucchini T., D'Errico G., Brusiani F., Bianchi G. M., A Finite-Element Based Mesh Motion Technique For Internal Combustion Engine Simulations, COMODIA 2008 Conference,

Sapporo, 2008.

3 - Brusiani F., Bianchi G. M., Lucchini T., D'Errico G., Implementation of a Finite-Element Based Mesh Motion Technique in an Open Source CFD Code, ASME ICES2009-76108

Paper, 2009.

4 - Lucchini T., D'Errico G., Brusiani F., Bianchi G. M., Tukovic Z., Jasak H., Multi-dimensional modeling of the air/fuel mixture formation process in a PFI engine for motorcycle

applications, SAE Technical Paper 2009-24-0015, 2009.