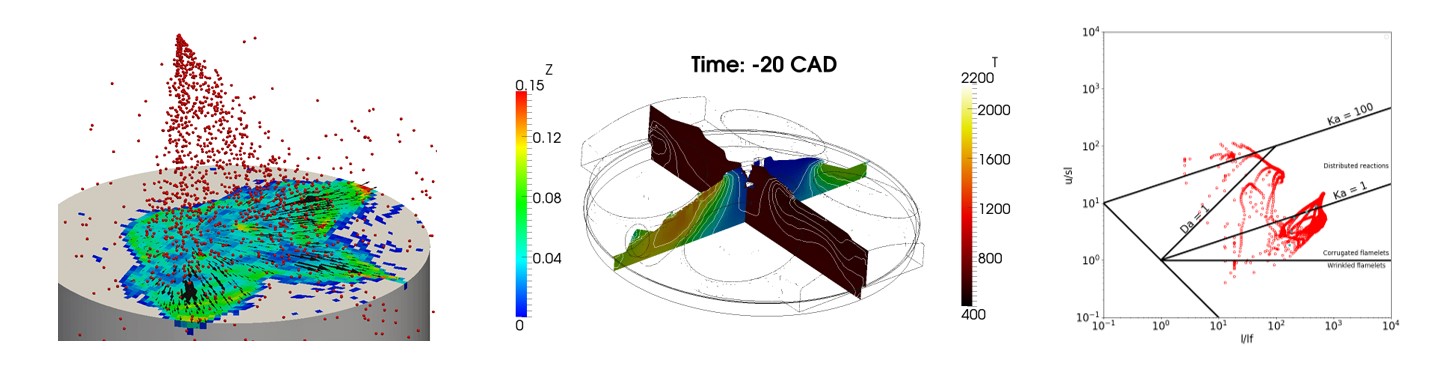

Particle laden flows

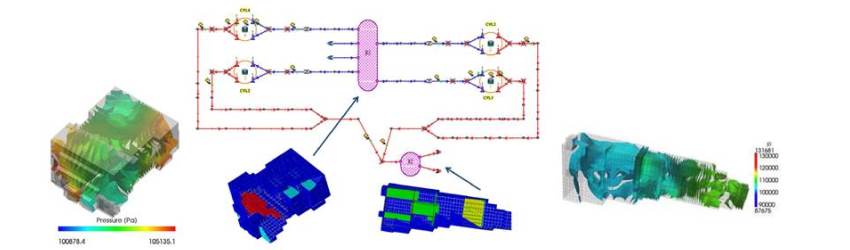

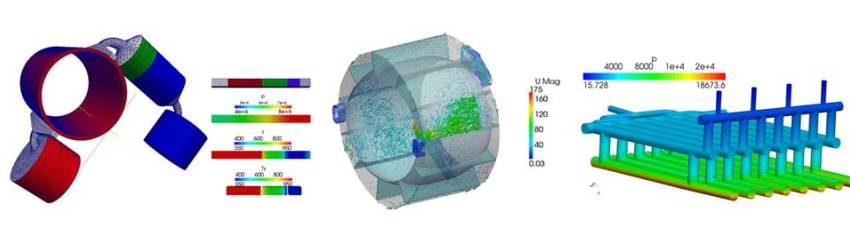

Lagrangian particles in the flow may be used to represent diesel soot particles. The increase of the soot cake layer thickness on the porous wall and its spatial distribution as a function of time have

been determined by the fully coupled particle-hydrodynamics in the gaseous flow, by calculating in the computational domain the rates of mass, momentum, and energy exchange between the gas

and particles. The influence of gas molecules-particle interaction on overall particle behavior is examined by including Brownian motion and partial slip in particle equation of motion.

Simulations help to highlight three-dimensional non-uniform particle deposition, mainly due to flow distribution in the micro-channel; the soot packing density and thickness on each face of the

computational porous cells are calculated.

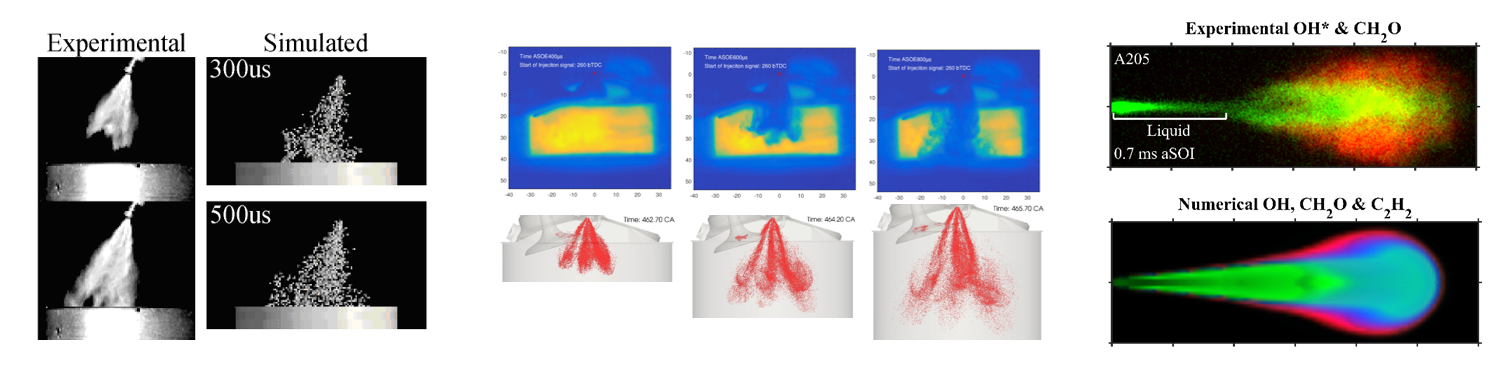

Lagrangian track of soot particles is performed in the computational domain. Particles deposits on the porous walls to build the soot cake.

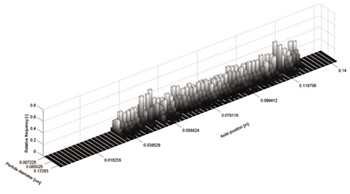

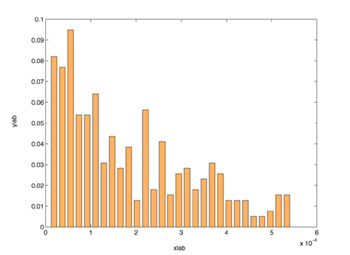

Diameter distribution of the soot particles building up the soot cake is monitored along the axial direction (a), as well as the relative frequency

of the particle Stokes numbers in the computational domain (b).

Selected publications:

1 - F. Piscaglia, A. Onorati, C. J. Rutland, and D. E. Foster. Multi-dimensional modeling of the soot deposition mechanism in diesel particulate filters.

In SAE Transactions, Journal of Fuel & Lubricants, SAE paper n. 2008-01-0444, SAE Int. Congress & Exp. (Detroit, Michigan), 2009.

2 - F. Piscaglia, C. J. Rutland, and D. E. Foster. "Development of a CFD model to study the hydrodynamic characteristics and the soot deposition mechanism on the porous wall of a

Diesel Particulate Filter". SAE paper n. 2005-01-0963, SAE 2005 Int. Congress & Exp. (Detroit, Michigan), April 11-14, 2005.